Hello all to the second of back to back JNQ wax recaps. These back to back JNQs take a lot out of both the athletes and coaches, so I needed a few days of recovery before getting the motivation to sit down in front of a computer screen.

There is pretty much one thing that you can always count upon when there is a JNQ in Itasca, cold weather. Without fail, temperatures went into the icebox for the first part of this weekend making waxing honestly slightly easier, if not more uncomfortable. When temperatures drop to single digits, there is very limited options that will make a ski feel better, meaning there is less I can do from a testing/application standpoint to give an advantage. In addition, because of our holiday sale, I made the trip up to Itasca on my own this weekend further limiting what I could do for testing.

12/21 - Skate Sprint

I actually made all of my glide test skis at the shop prior to leaving for Itasca which helped limit the amount of time I spent outside. I prepped all test skis and race skis for both Saturdays and Sundays race with Rex NF31. This has been one of the most consistent cold waxes in natural/mixed snow conditions. Because they got a little bit of snow from a previous storm system and they were planning on using some of the natural snow trails for Sundays distance race I decided to lean towards Rex NF31. If everything was man made at these temperatures I probably would have swapped to Swix TSP5 as my race paraffin.

For glide I tested a couple of liquids and roto blocks that could potentially make a difference, but I made sure to leave my paraffin in the open as a control for the test. There is always a good chance that a race paraffin will be better than any top coat when the conditions get this cold. Below is my results from the race:

Glide Test:

1a - Rex NF31

1b - Rex Olos Powder

2a - Rex NFX Blue Block

2b - Star Cold Liquid

3a - Rex NF31 (Corked)

3b - Star Cold Block

Results:

1B>1A

2A>2B

3A>3B

1B>2A

3A>1A

3A = Winner = Rex NF31 Hand Corked

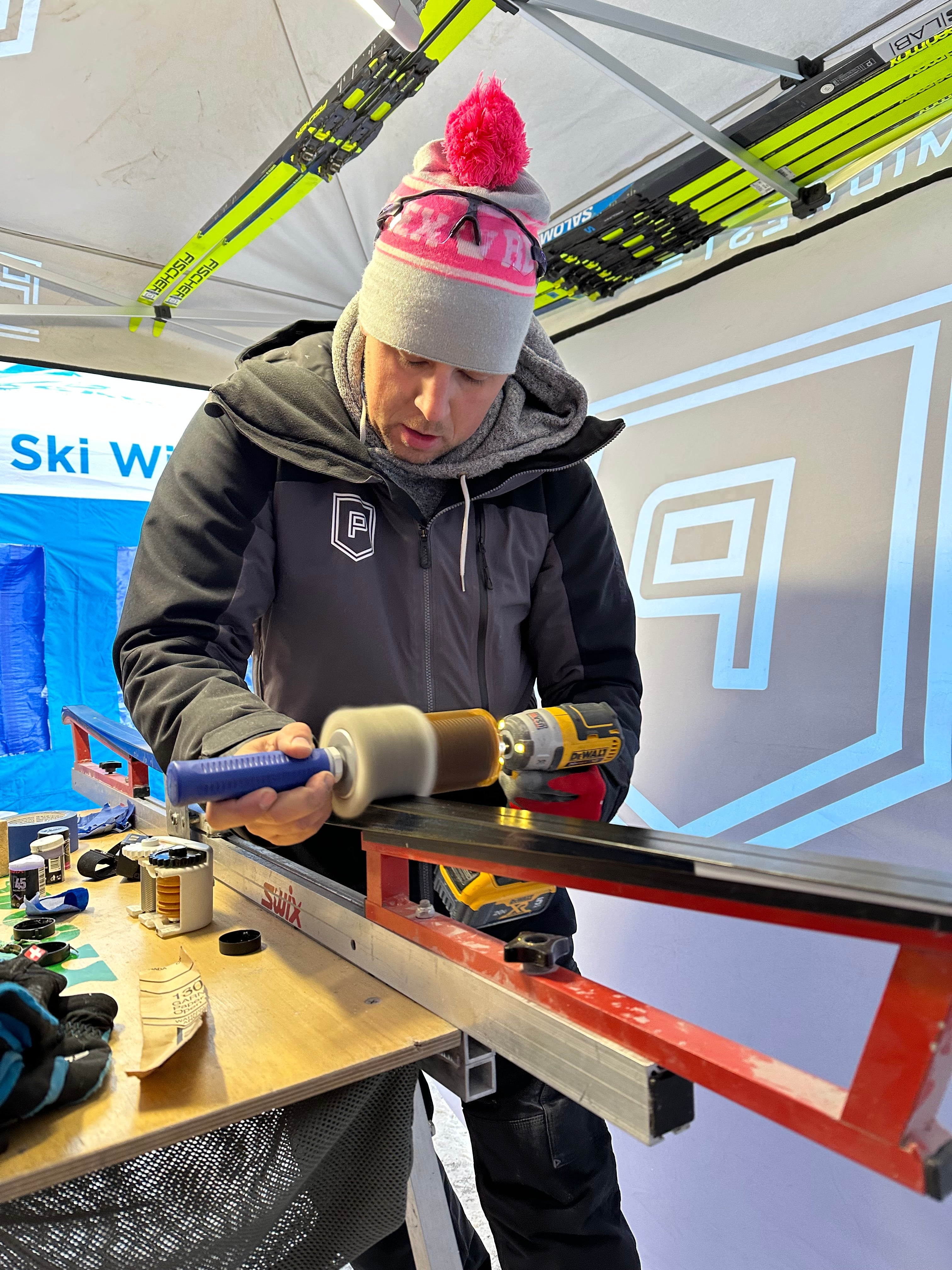

This was a really interesting test for a couple of reasons. The first is that there was only 1 ski that felt like it helped increase speed at all (3A). All of the other skis had very limited, if any differences in ski speed. The ski with Rex NF31 hand corked was the only one that felt noticeably faster. The second reasons this was interesting is because of what actually won the test. A couple years ago when I was was up here for for a different cold JNQ the batteries on all of my drills ran out and I had no other access to power. I was trying to figure out a way to apply NF31 as that won my test and I ended up just crayoning the wax directly to the ski without heat, and then buffing it in with a hand cork. This worked so well a couple years ago that I decided to throw it into the test again this year. Turns out the dumb mistake I made a couple years ago is actually a great way to apply this wax and speed the skis up in cold conditions. I will probably be testing this method again at the next Itasca JNQ in February which I have already seen the forecast for, it will definitely be cold!

12/22 - Classic 7.5km

Moving onto the classic race, I knew that I was going to be very limited in what I could test/apply on my own. I was not going to get any time to test glide, and ended up throwing some Rex NF21 liquid onto the skis as the weather had warmed up a bit more than I was expecting it to. Rex NF21 liquid is one of those waxes that is super safe and I am happy to apply without testing knowing that it will nearly always be in the mix.

I did some preliminary testing the day before to find a good binder. The course was fairly abrasive so I needed to use a binder that had a decent amount of durability, but it was also the type of course that did not favor striding so I wanted to favor having fast skis for my athletes. The course at Itasca is great for skating with a lot of short, punchy climbs. But this type of a course creates conditions for classic skiing where you are either herringbone or double poling. The binder that I ended up working with was Rex Liquid Klister base + Rex Base wax ironed together. The liquid klister was is great to help boost durability, while the base wax helped to speed it up and hide the klister on the natural snow sections of the course.

For the main kick wax, I thought it was going to be one of those days where you could choose your blue wax from any companyand that would be good enough. The tracks ended up glazing a little bit which meant that I needed to wax warmer than I originally anticipated. I ended up going through a progression of waxes while testing in the morning. I started with a core of 4 kick waxes that I thought would run well on their own:

Kick Test:

1a - Rex Blue -2…-8

1b - Swix VP40

2a - Rode B17

2b - Guru Violet

Results:

1a - Fast, Decent kick

1b - Fast, Decent kick, similar to 1a

2a - Really fast, not enough kick

2b - Slow, ok kick

Rex Blue -2…-8 and Swix VP40 were both very similar in testing, good speed and pretty good kick. I knew that I could increase kick on both of those skis easily by going to the next wax up in the lineup. I chose to work with the Rex waxes the rest of the day because that is the line I am the most comfortable and knowledgeable with.

The next progression in the testing I added a couple layers of Rex Blue Special -1…-4 on top of the -2…-8 to see how much kick it added and if it slowed the ski down at all. It did add quite a bit more security to the kick and only slowed it down a little bit. I thought this trade off was worth it. I worked with this combination for the rest of the day. Later on as the track had even further glazing I added 1 layer of Rex 30GB to the last bit to help solidify the kick. With the extra moisture coming out in the natural snow 30GB helped to keep the wax job stable and secure for the entire race.

Takeaways

I went into this season wondering if I could pick one company and wax skis for an entire weekend using that wax line and still have competitive skis. I ended up being able to put that to the test during this weekend while I was working on my own. Not everyone has access to a massive wax box, or a fleet of test skis to be able to put the time in to test a huge range of waxes. Choose a company you are familiar and comfortable with and you will be able to make good skis.

A second takeaway is to look at notes from previous races at either similar conditions or locations. You may find some patterns of waxes or applications that work well specific to a location or condition that you can use to your advantage.

Whats Next?

I will be looking forward to a nice break over the holidays from the shop in Europe. I am going to be heading to Italy for the second half of the Tour de Ski working with the Rex Racing service. I will be testing and selling Rex waxes at the Tour to various world cup teams. In addition, I will be staying for an additional 3 or 4 days after the races are finished to test new products at the venue for next years Olympics. There are some new products in development that we want information from and there is no better place to test that at than the future Olympic race course.

I will be giving some social media updates on my trip to Italy, but for those looking for my next race report, it probably will not happen until the end of January after the next JNQ at Theodore Wirth Park.